Model: WT-C85/100/120

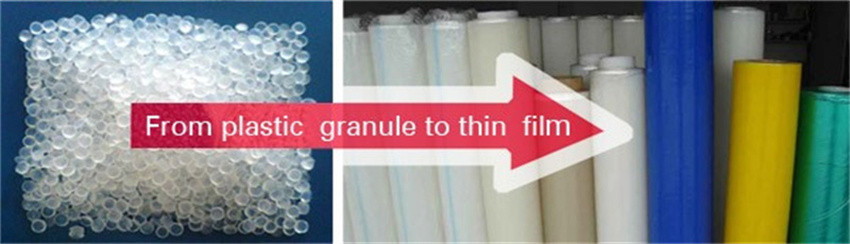

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps in crease the production capacity. It is applied to blowing the plastic films like low density polytene (LDPE), high density polytene (HDPE) and linear low density polytene (LLDPE), It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

1) It is used for blowing high-low pressure polyethylene, which has been widely used for producing laminating films, packing films, agricultural covering films,bags or films for textile and clothing and other packing materials.

2) The main motor adopts frequency control of motor speed to improve the speed regulating stability of main motor and save electricity by 30%.

3) The screw and material barrel adopt 38 chrome-molybdenum aluminum which has been nitrogen treated and the traction frame adopts lifting type.

4) No matter what size the film is, big or small, it can achieve the best effect of cooling.

|

Model |

WT-C85 |

WT-C100 |

WT-C120 |

|

Raw Material |

HDPE, LDPE, LLDPE; Virgin and Recycled |

||

|

Film Width |

1800mm |

2000mm |

2500mm |

|

Average Output |

120Kgs |

200Kgs |

220KGS |

|

Film Thickness |

0.01mm-0.2mm |

||

|

Power supply |

380V, 3Phase, 50Hz |

||

|

weight |

4000kgs |

5000kgs |

7000kgs |

|

Dimension |

7×3.8×7M |

8×4×7M |

9×4.5×9M |

|

Screw&Barrel Diameter |

85mm |

100mm |

115mm |

|

Screw&Barrel L/D ratio |

32:1 |

||

|

Motor |

55KW |

75KW |

105KW |

|

Gearbox |

225 |

250 |

300 |

|

Die Head Type |

Rotary Die Head |

||

|

Die Size |

200/400 |

250/500 |

400/800 |

|

Heating |

40KW |

55KW |

100KW |

|

Blower |

7.5KW |

||

|

Upper Tower |

Rise and Fall |

||

|

Roller Length |

2000mm |

2200mm |

2500mm |

|

Roller Working Way |

Opened and Tightened By Air Cylinders |

||

|

Take Up Motor |

|||